At Jetcut, we can cut any metal, from 0.5 mm to 170 mm thick to a best tolerance of +/- 0.008″/0.2mm for the Laser and Water Jet, and +/- 0.08″/2mm for the Plasma. We have the capacity to cut from metal sheets up to a size of 4m by 2m on the Laser & Water Jet, and 6m by 2m on the Plasma.

The benefits of Laser Cutting include:

The benefits of Water Jet Cutting include:

Steel (Mild & Stainless) is ideal for cutting using Plasma, Laser and Waterjet, even after it has been hardened (with minimal slow-down of cutting speed). Plasma can cut Steel from 3mm to 80mm thick, Laser from 0.5mm to 25mm thick and Waterjet from 0.5 to 170mm thick. Waterjet also does not involve heat therefore will create no Heat Affected Sone and therefore can be ideal for heat sensitive items.

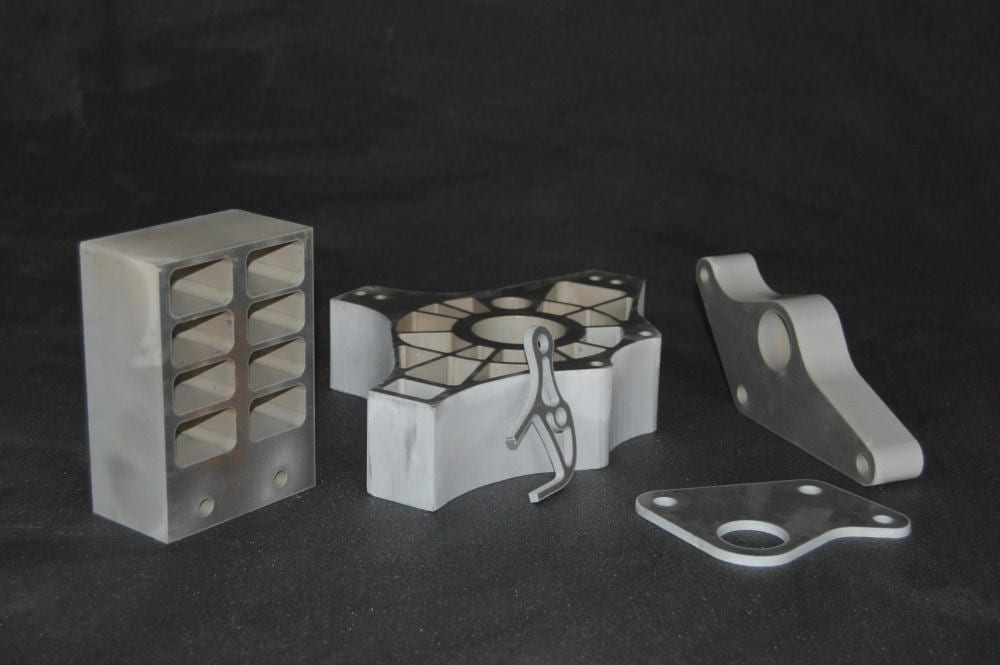

Aluminium is a light weight but strong metal used in a wide variety of applications. Aluminium is a relatively soft metal and can be difficult to machine. Our laser can cut Aluminium up to 8mm, however, abrasive waterjet cuts Aluminium extremely well up to 170mm thick.

Copper & Brass are also challenging materials to machine and cut, but Water Jet systems make cutting Copper and Brass easy. Both Copper and Brass are impossible to cut on a conventional laser due to reflection. It is also difficult to machine conventionally, because it tends to gum up conventional cutting tools. Water Jet Cutting is the most appropriate solution for copper & brass.

Titanium Exotic and expensive materials that might otherwise be quite difficult to machine like hardened tool steel, stainless steel or titanium are well suited to abrasive waterjet cutting. One of the huge advantages of cutting materials like titanium using this technique is that you can significantly cut costs as tight nesting means the material is highly utilised and offcuts can often be re-used.

Tool Steel is difficult to machine conventionally, particularly once it’s hardened, but is fairly easy to profile with Water Jet Cutting. Steel can be hardened before or after cutting. Steel hardness has only a minor effect on the rate at which it can be machined with Water Jet.

At JetCut we are a BS EN 1090 and ISO 9001:2015 accredited company and have over 20 years experience in Engineering and Profile cutting

© Copright 2020 JetCut Ltd | Terms | Legal Information | Privacy | Copyright