Menu

Cutting your parts using laser or abrasive waterjet is straightforward:

We’re ready to cut, and make the part to tolerances of around +/- 0.1mm for Laser Profiles and +/- 0.2mm for Water Jet Cut profiles.

Laser Cutting is a technology which uses a laser to cut metal (steel & aluminium) to a high degree of accuracy (+/- 0.1mm) and at high speed.

Plasma Cutting is a process that cuts through steel by means of jet of hot plasma. JetCut’s Voortman V310 also has Bevel Cutting, Drilling, Tapping, Counter Sinking and Counter Boring capabilities.

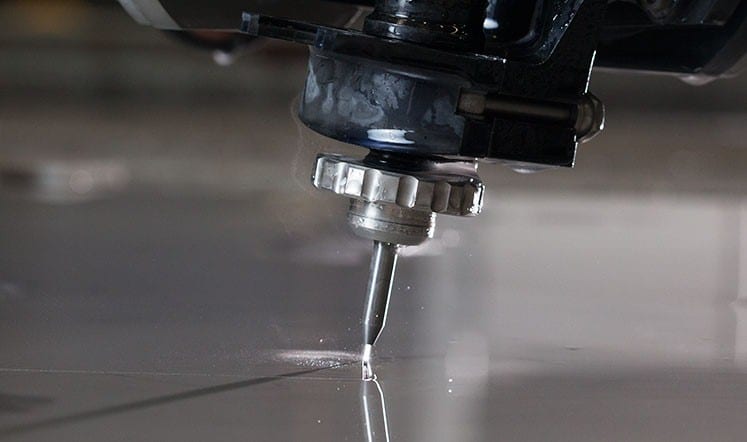

Water Jet Cutting is a technology which uses a combination of extremely High Pressure Water (60,000 psi) and a fine abrasive (Garnet) to cut virtually all materials (all metal, plastics, stone, wood etc) to a high degree of accuracy (+/- 0.2mm). Water Jet Cutting works by forcing the high pressure water through a diamond orifice (0.1mm diameter) and then adding the abrasive just before the jet, now 1mm diameter, hits the surface of the material. JetCut’s Water Jet Cutting machines are specifically designed for flat sheet material from 0.5mm to 170mm thick and from sheet sizes up to 4000x2000mm.

At JetCut we are a BS EN 1090 and ISO 9001:2015 accredited company and have over 20 years experience in Engineering and Profile cutting

© Copright 2020 JetCut Ltd | Terms | Legal Information | Privacy | Copyright